Companies continue to be brought down by the demise of a key supplier. Neil Hodge provides some guidelines on avoiding the pitfalls

Last December, the UK’s largest independent entertainment retailer Zavvi was forced to go into administration when it was crippled by the collapse of Woolworths’ wholesaling division Entertainment UK. The wholesaler was Zavvi’s main supplier, and its demise left the store unable to take customer orders.

The high-profile collapse provides two invaluable lessons: first, don’t be over-exposed and overly dependent on a single supplier and, secondly, any company – no matter how big – can go bust and potentially take your organisation with it.

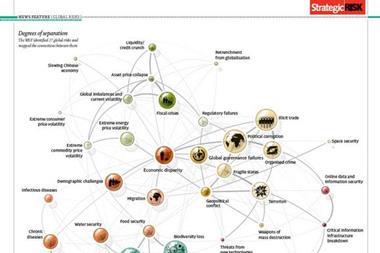

In a recent survey called ‘Risks in 21st century supply chains’, published by insurance broker Aon, 91% of respondents reported that their supply chains had inherent risk, up from 78% in the 2008 survey. In a November survey of 40 chief procurement officers or equivalent executives, management consultancy Accenture found that more than 70% were more closely monitoring the financial stability of their suppliers and almost three-

quarters were increasing their focus on supplier relationship management. The same survey also revealed that nearly 20% of respondents reported that their suppliers were unable to meet their supply levels or needs, an,d for almost 15%, suppliers had been put out of business or forced to merge with other companies.

Even for firms such as Intel, the US semiconductor manufacturer, which outsources only about 10% of its production, stepping up the level of scrutiny of its external suppliers is an important strategy. ‘We’re having to watch our supply line and make sure of their financial health and whether they can stay in business and are financially sound,’ says Brian Krzanich, the company’s vice-president and general manager of manufacturing and supply chain.

Crunch time

The credit crunch has highlighted the precarious nature of some companies’ dependence on specialist or niche parts manufacturers. In Germany, car manufacturer BMW was forced to bail out one of its key suppliers when it filed for insolvency in February. The luxury car maker was about to introduce its new Z4 convertible, and Edscha, a German manufacturer of sun roofs, door hinges and other car parts, was contracted to supply its roof.

A BMW company spokesman said: ‘We had no choice. To go to another supplier would have taken six months and we don’t have that. We had to help Edscha and try and stabilise it.’ Edscha is still trading, but BMW remains so worried about disruption to its supply chain that it has increased the number of staff in its risk monitoring department to look only at components makers.

The incident has prompted some of Germany’s largest manufacturing firms to re-evaluate their supply chains, and to leverage their clout to secure their own positions and gain a competitive advantage by speeding up efforts to cut the number of suppliers they use. Car parts makers Continental and Schaeffler recently agreed on sourcing co-operation that would cut the number of their 5,600 suppliers by half. Siemens, Europe’s largest engineering group, even said it would cease ordering from as many as 74,000 suppliers this year; a fifth of its 370,000 purchasing partners.

‘Such programmes have become very popular,’ says Martin Raab, head of supply chain management at Capgemini Consulting. ‘Purchasing often adds up to 60% to 80% of overall costs. This is something where you can save a lot of money very quickly.’

Many car industry executives hope that the crisis will lead to the long sought-after consolidation and reduction of capacity in the fragmented supplier industry. BMW has in recent years reduced the number of its suppliers. The premium carmaker has also been talking to arch rival Daimler about co-operation, involving joint purchases. ‘Consolidation among suppliers will accelerate significantly,’ says Herbert Diess, head of purchasing at BMW. ‘For us, this is the preferred way to make the industry more competitive.’

Nick Wildgoose, global supply chain product manager at insurer Zurich Global Corporate, says: ‘Supply chain management is still being ignored by a lot of companies as a potential high risk area, even though the possible damage to the company caused by any disruption in the supply chain can be massive.’

‘Organisations are more dependent on suppliers providing goods and services now than they ever have been before,’ Wildgoose says. ‘The growth of outsourcing as a way to reduce costs and the global nature of it, such as having telephone operators in India and so on, can mean that major business operations are being carried out in far-flung locations, thousands of miles away from the organisation’s actual market. This means that they can be difficult to audit regularly, and, as a result, if anything goes wrong with the supply chain, it can be more difficult and expensive to fix.’

“The credit crunch has highlighted the precarious nature of some companies’ dependence on specialist and niche parts manufacturers

Paul Howard, head of insurance and risk management at supermarket chain Sainsburys and chair of the Association of Insurance and Risk Managers (AIRMIC), says that, as a first step, organisations need to conduct regular due diligence to keep on top of any potential issues. ‘Supply chain management has always been a crucial area to our business and it is always highly placed on our risk agenda,’ he says.

Know every link

Howard says that organisations need to determine who their key suppliers are – essentially, the companies that could cause the most disruption to the organisation if they were to halt delivery for whatever reason – and work with them to develop and test a contingency plan that will allow them to still supply goods (to your company at least). ‘We have regular meetings with our key suppliers, which can take place on a monthly basis. We conduct these at their premises and we assess their business continuity plans, trading risks, supply chain arrangements and risks, and solvency so that we are satisfied that risks are being managed appropriately,’ he explains.

Companies should also insist on knowing who their sub-suppliers are, and consider carrying out site checks at their operations. ‘The clue to the issue is in the words: supply chain,’ Howard says. ‘Just looking at the companies that you directly source from will only give a very superficial review of the strength of your supply chain management programme. Organisations need to look deeper and see who their suppliers are sourcing from, and find out whether they are asking the same questions that you are asking of them.’

Howard also says that risk managers need to test the resilience of their own contingency plans and continually look for weak spots, such as reliance on single-source suppliers, or geographic areas that may be providing a disproportionate amount of goods. ‘You need to look hard at the arrangements that you have in place and ask whether they are still appropriate and if the level of risk associated with them is still low. What may have been a suitable, low-risk arrangement last year may not look so attractive now, and so arrangements may need to be revised quickly,’ he says.

Wildgoose recommends that risk managers should carry out a simple credit check on a supplier by using credit information providers, such as Experian, Equifax and Dun & Bradstreet, to check their credit worthiness, as well as search through news cuttings to see if the company has had any history of supply chain failings, late payment problems, or regulatory censure. ‘Carrying out in-depth background research on your suppliers – particularly in the current economic climate – is an absolute must. Yet there is no substitute for having strong controls and procedures in place to make sure that the goods and services that you have bought from a supplier are delivered on time, to specification, and on budget.’

A mixture of incentives, such as putting some firms on a ‘preferred supplier’ list, and penalties, such as charging for late or wrong delivery, can also help to ensure that suppliers ship their orders on time, Wildgoose says. ‘Having strict credit terms helps increase a company’s working capital and is also useful in flagging up late or overdue payments, which can be a significant warning sign about a company’s financial health. However, only regular credit checks will be able to determine whether the company will still be solvent in a few months’ time,’ he adds.

Help for suppliers

As well as preserving one’s own organisation from supply chain failure, some experts believe that firms can also help keep their suppliers out of danger with little effort. Mark Perera, chief executive of think-tank Procurement Intelligence Unit, says that the relatively new concept of supply chain finance could offer much needed support. Leading companies such as Sainsburys, Volvo, Syngenta, Nike and Royal KPN all use supply chain finance as a way of keeping their suppliers in credit.

The theory behind it is relatively simple: for example, a baker supplies a supermarket with 1,000 loaves of bread every day at a total cost of £5,000 per week. Ordinarily, the baker would then invoice the supermarket and wait 30 days for the invoice to be settled, depending on what credit terms had actually been agreed.

However, due to the credit crunch, the baker needs the invoice to be settled earlier so that it can continue its operations, yet the bank is reluctant to lend enough funds at a fair rate based on the baker’s risk and credit profile. Under supply chain finance, however, the baker could receive an early payment by using the supermarket’s credit facility with its own bank. This means that the supplier is paid quickly and does not need to use an expensive overdraft facility, and that the buyer does not need to pay the bank back until the full term. In turn, this means that both companies have enough working capital available to continue to operate. It’s an easier solution than bailing the supplier out, says Perera.

‘Our analysis has found that those organisations embracing the supply chain finance model have shored up their supply chains, ensuring the increased availability of working capital for both themselves and their suppliers,’ he says. ‘Our estimates show that even if only a proportion of the UK’s largest organisations implemented it, billions of pounds of working capital could be freed up,’ he says.

Top tips

1) Communicate: The first step that any

organisation should take in checking their supply chain is to talk to their suppliers regularly and carry out site visits. Building a close relationship will encourage suppliers to alert you quickly if they are experiencing any problems.

2) Determine key suppliers: Work out who your key suppliers are and assess what your organisation’s potential risk exposure could be if one of these suppliers either failed or closed your account.

3) Have an early warning system: Changes in credit terms, prices and delivery times could all potentially highlight major supply problems. Be prepared to question such changes.

4) Carry out credit checks: Credit information organisations like Experian will have details about how quickly organisations settle their bills. The longer a company takes to pay up, the more stringent your own credit terms should be.

5) Check your exposure: Sourcing key materials from a single supplier is high risk, so try to source from more than one company. Check different suppliers for their interdependence, however. If one supplier fails, others may follow in a domino effect.

Postscript

Neil Hodge is a freelance writer

No comments yet